Laboratories/ المعامل

(1)

TOOTH BRUSHING SIMULATOR

- The device simulates various brushing movements on the surfaces of tested material.

- The individual specimens may be of various forms and materials (hardness), and may be loaded with various levels of contact pressure.

- The specimen chambers are separated from each other so that each specimen can be operated with its own liquid (e.g. toothpaste-water mix).

- A high-grade motion controller guarantees exact speeds and trajectories which can be adjusted with a very high degree of precision.

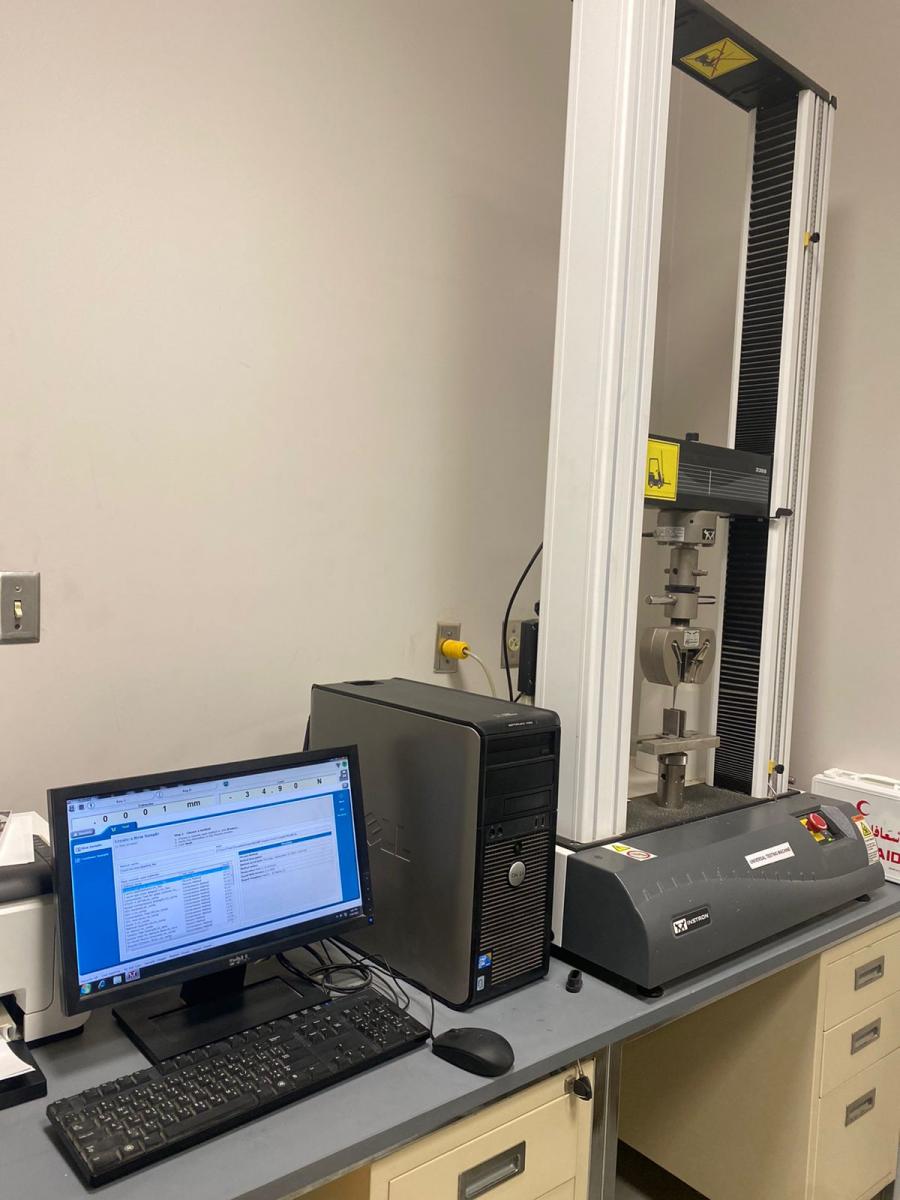

(2)

UNIVERSAL TESTING MACHINE

- A universal testing machine is used to assess the strength of materials

- This device is used to test specimen for tensile strength, compressive strength, shear strength, other important laboratory test

- This device measures the mechanical properties in static conditions.

(3)

CHEWING SIMULATOR

- A chewing simulator is a device that simulates the chewing process for dental samples.

- This device is used for fatigue testing, and to measure resistance to fracture and wear of a material.

- The individual specimens may be of various forms and materials (hardness), and may be loaded with various levels of contact pressure.

- The specimen chambers are separated from each other so that each specimen can be operated with its own liquid

- A high-grade motion controller guarantees exact speeds and trajectories which can be adjusted with a very high degree of precision.

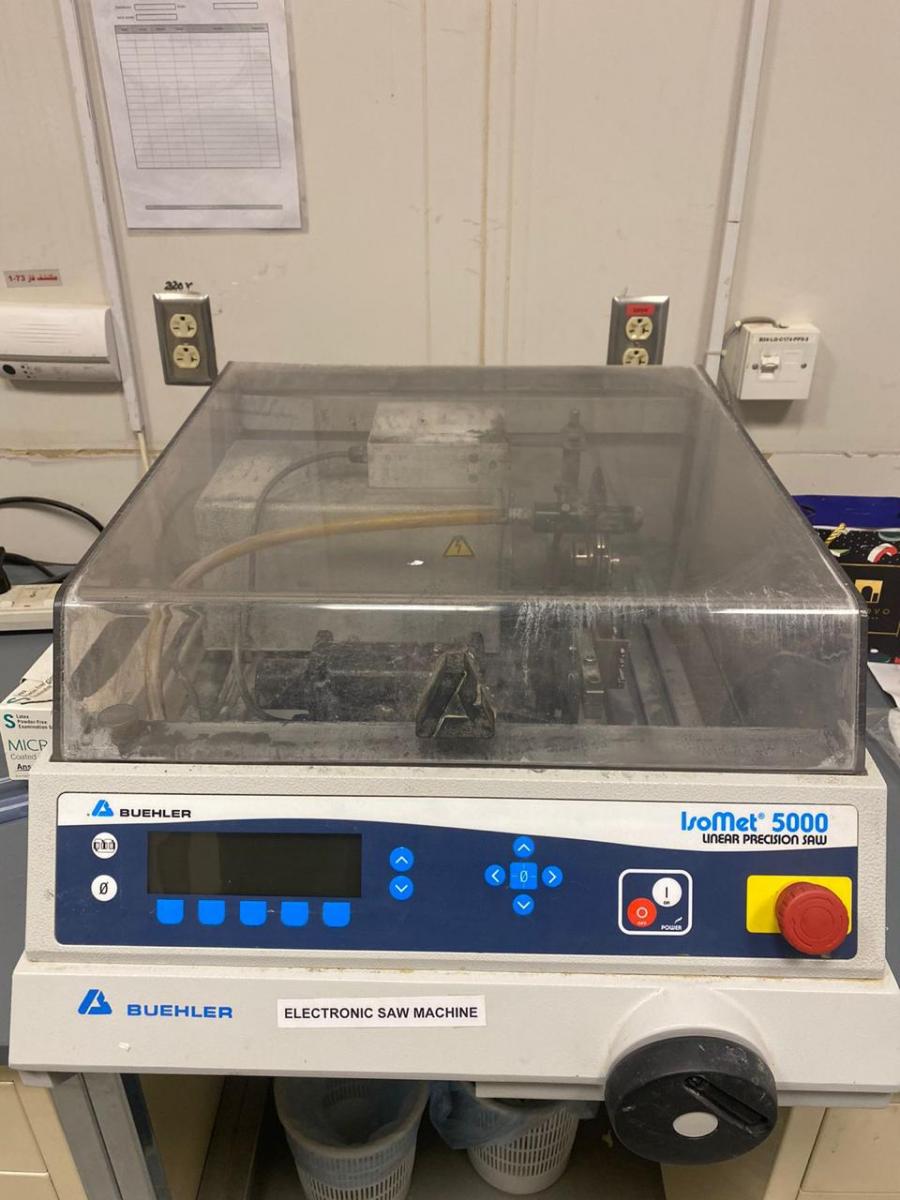

(4)

ELECTRIC SAW DEVICE

- This device is used for sample preparation in varying dimensions

- It is used for precision cutting of the samples

- The device is equipped with water coolant for cooling down the samples during cutting

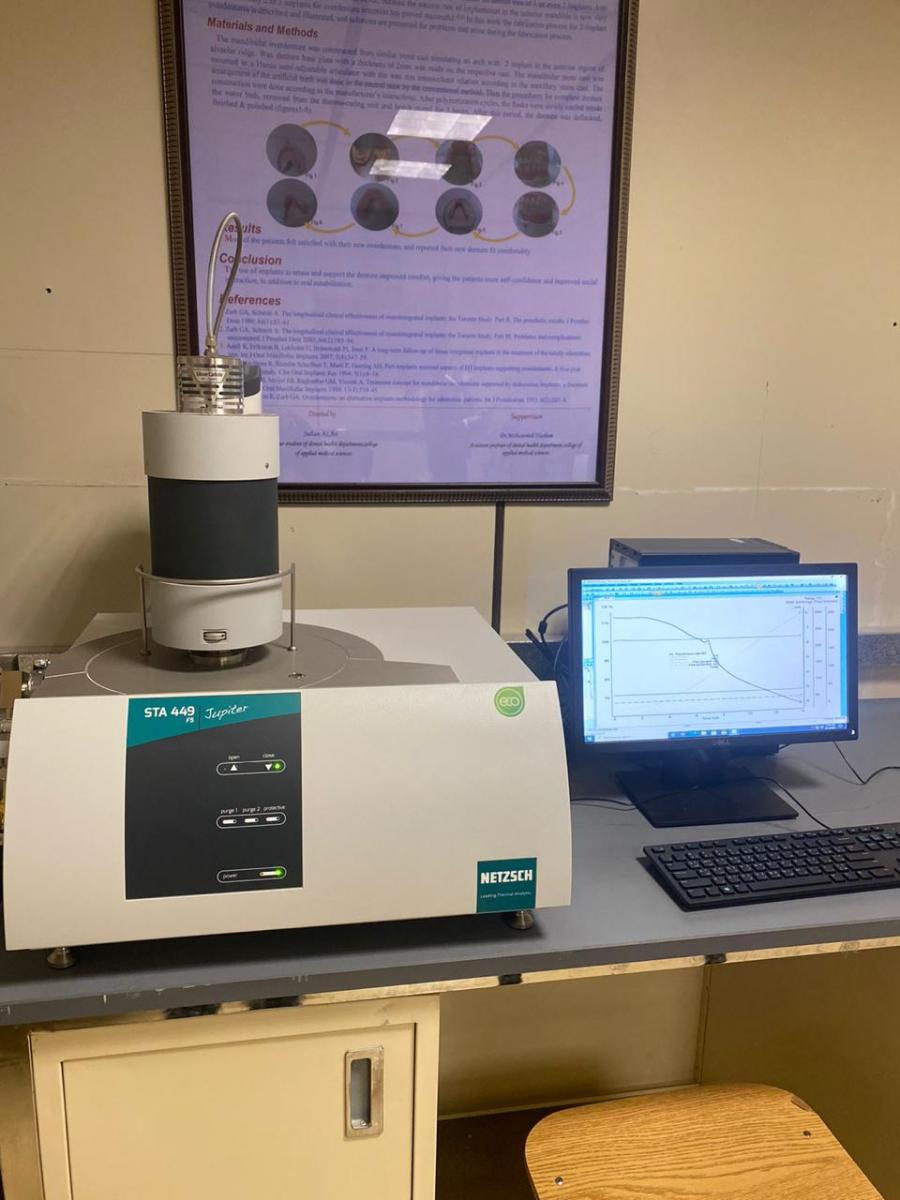

(5)

THERMAL ANALYZER

- This device is used to determine simultaneous changes of mass (TG) and caloric reactions (DSC) of a sample in the temperature range from 0°C up to 1600°C.

- It measures heat flow and weight changes in sample material at varying temperarure.

- The device measures how much a sample absorbs or releases energy during heating or cooling.

(6)

NANOMECHANICAL TESTER

- Provide precise, reliable and repeatable measurements of hardness, Young’s modulus, and other mechanical properties of the materials.

- It provides mechanical properties of a material at nano level

- It can generate the graph between applied load and deformation

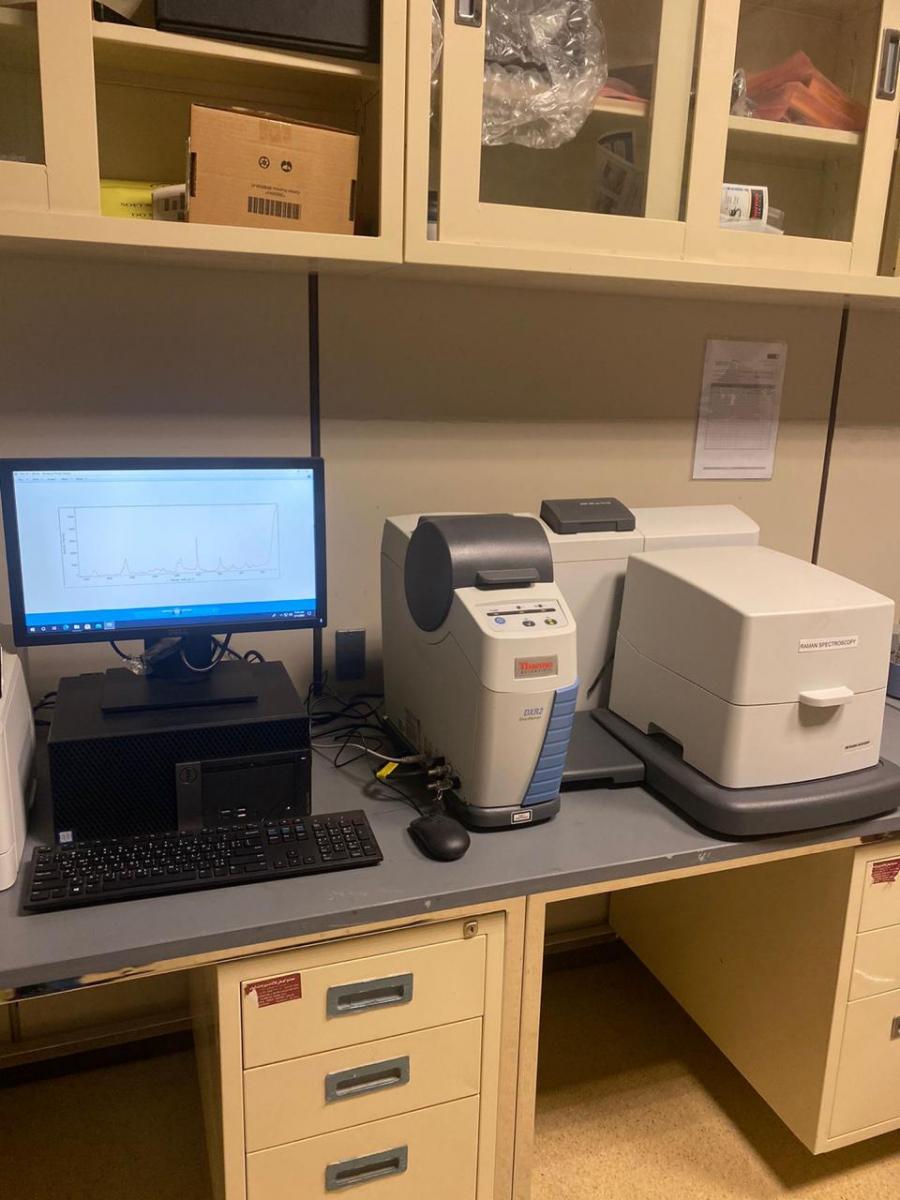

(7)

RAMAN SPECTROSCOPY

- Raman Spectroscopy is a non-destructive chemical analysis technique which provides detailed information about chemical structure, phase and polymorphy, crystallinity and molecular interactions

- It is based upon the interaction of light with the chemical bonds within a material.

- Typically, a Raman spectrum is a distinct chemical fingerprint for a particular molecule or material, and can be used to very quickly identify the material, or distinguish it from others

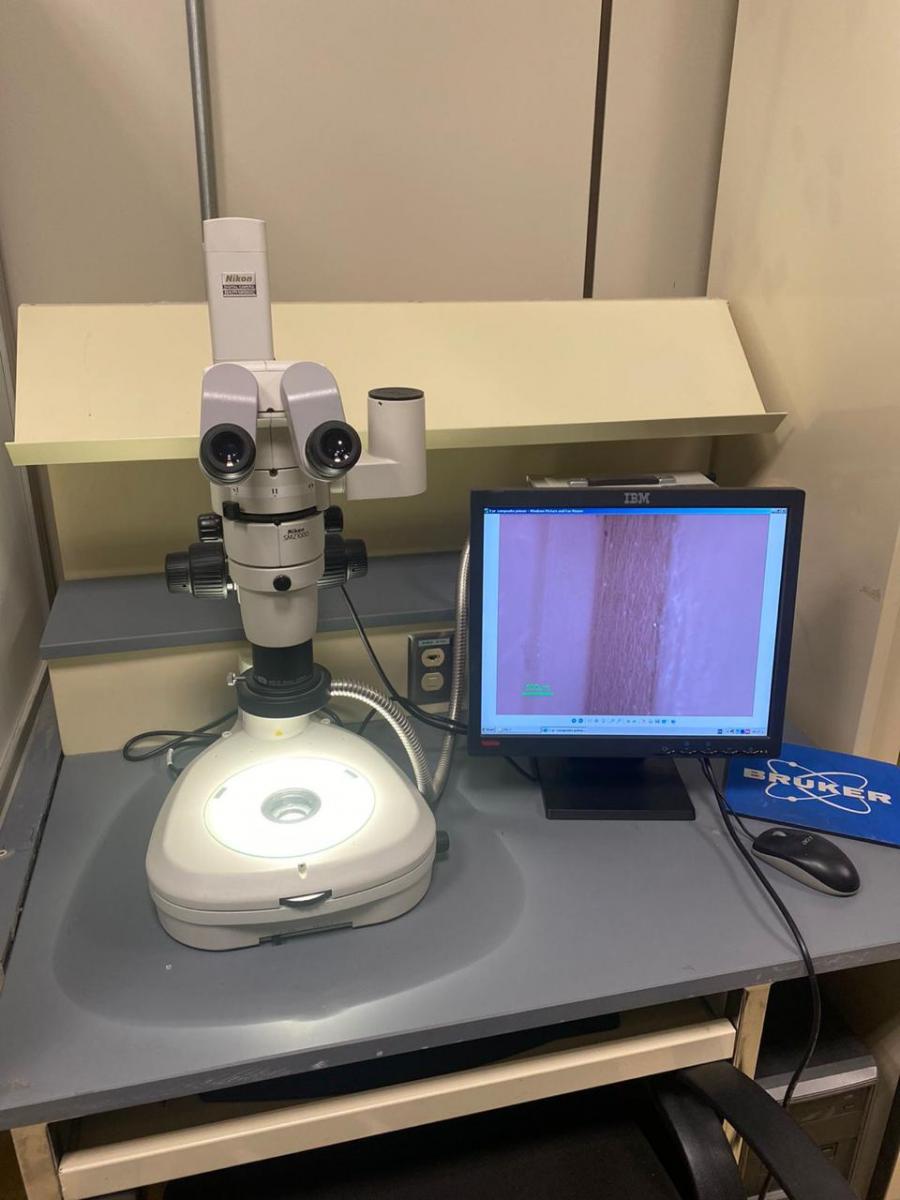

(8)

STEREOMICROSCOPE

- The device is used for visualization of the samples.

- The attached lens can magnify the sample upto 25X.

- The images can be generated using a software.

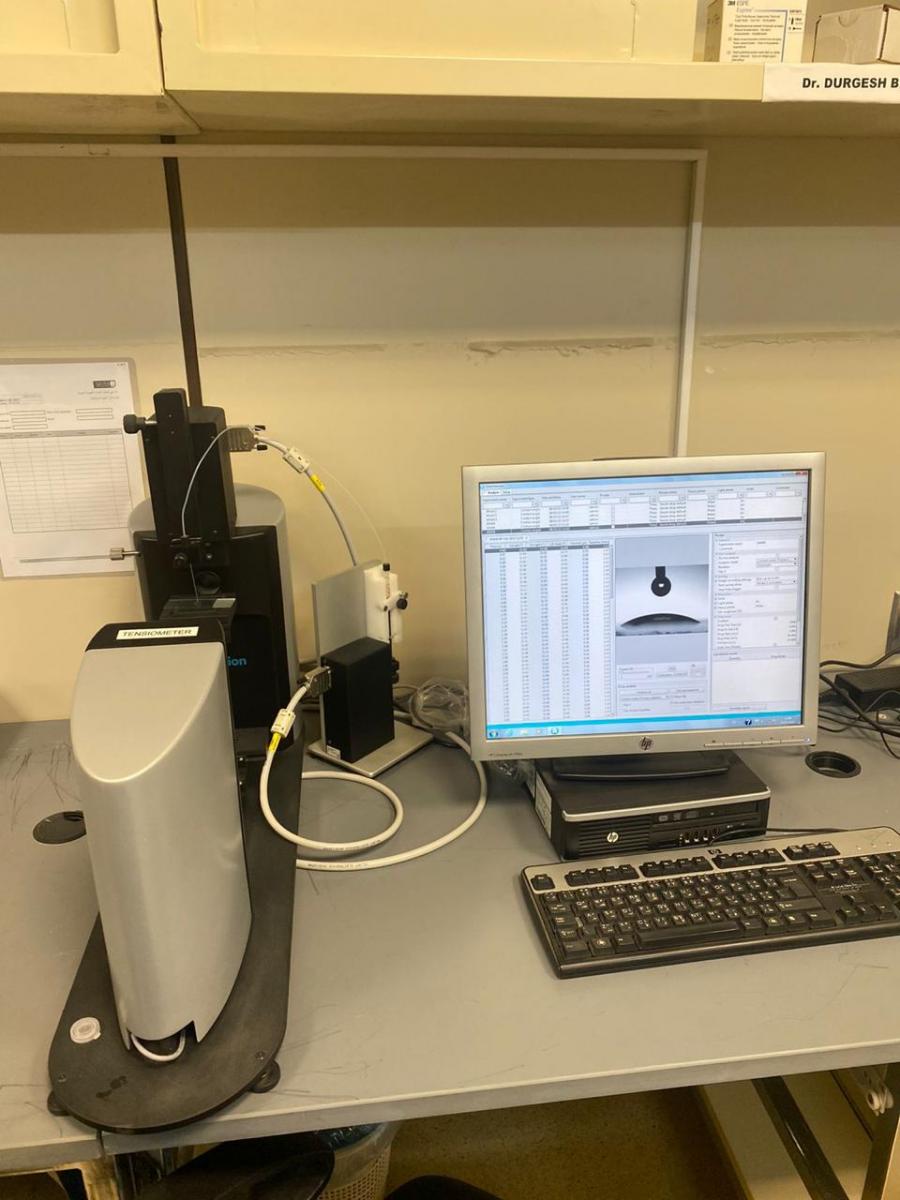

(9)

TENSIOMETER

- Provides useful information about the wetting characteristics of a surface and a liquid.

- By using different probe liquids with known polar, non-polar, hydrogen-bond energy components, the surface free energy of a solid surface can be determined through contact angle measurement.

- The hydrophobicity and hydrophilicity of a material can be measured with this device.

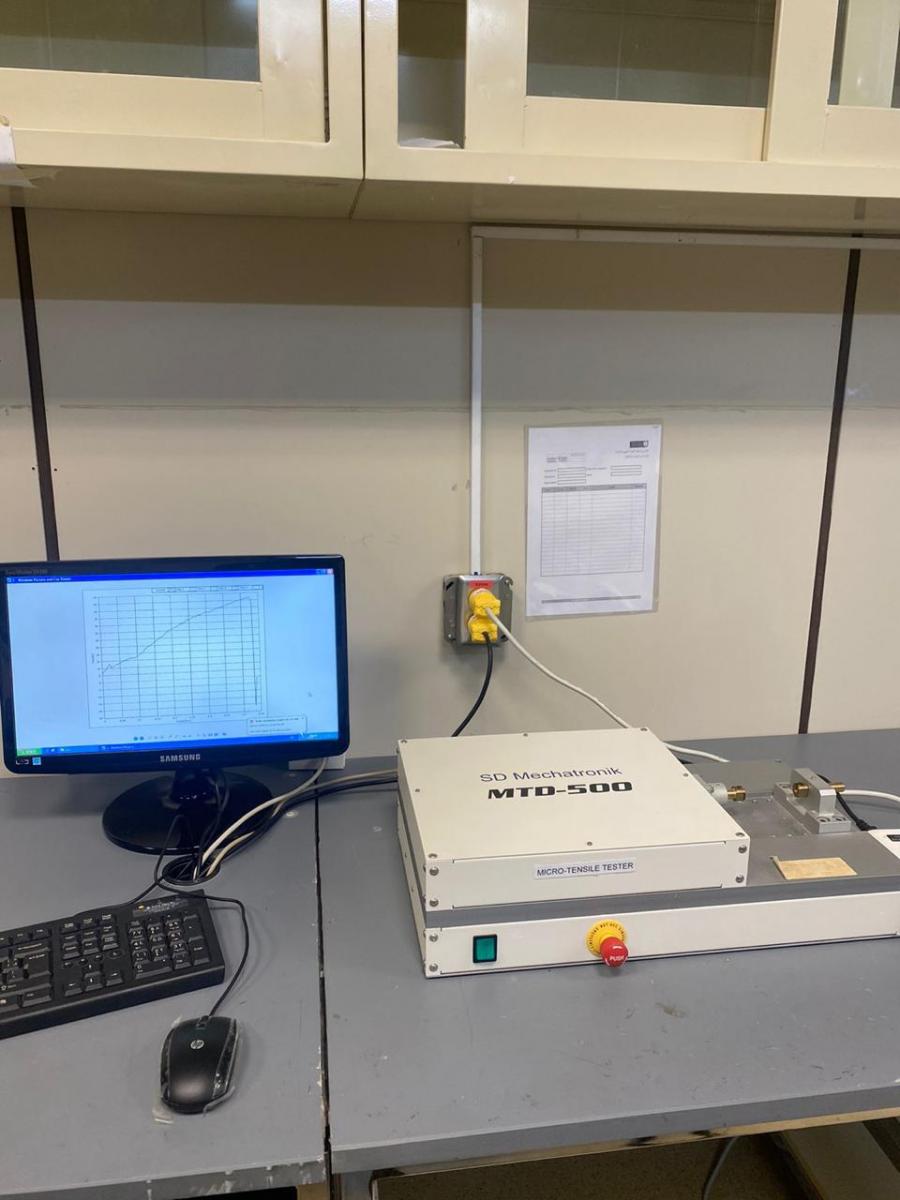

(10)

MICROTENSILE TESTER

- The tensile property of a material at micro level can be measured

- Micro-tensile testing can be used to quantify the mechanical properties of individual interfaces or phases within a material

- In addition, measurements on the microscale can be used to detect and investigate single plastic deformation mechanisms.

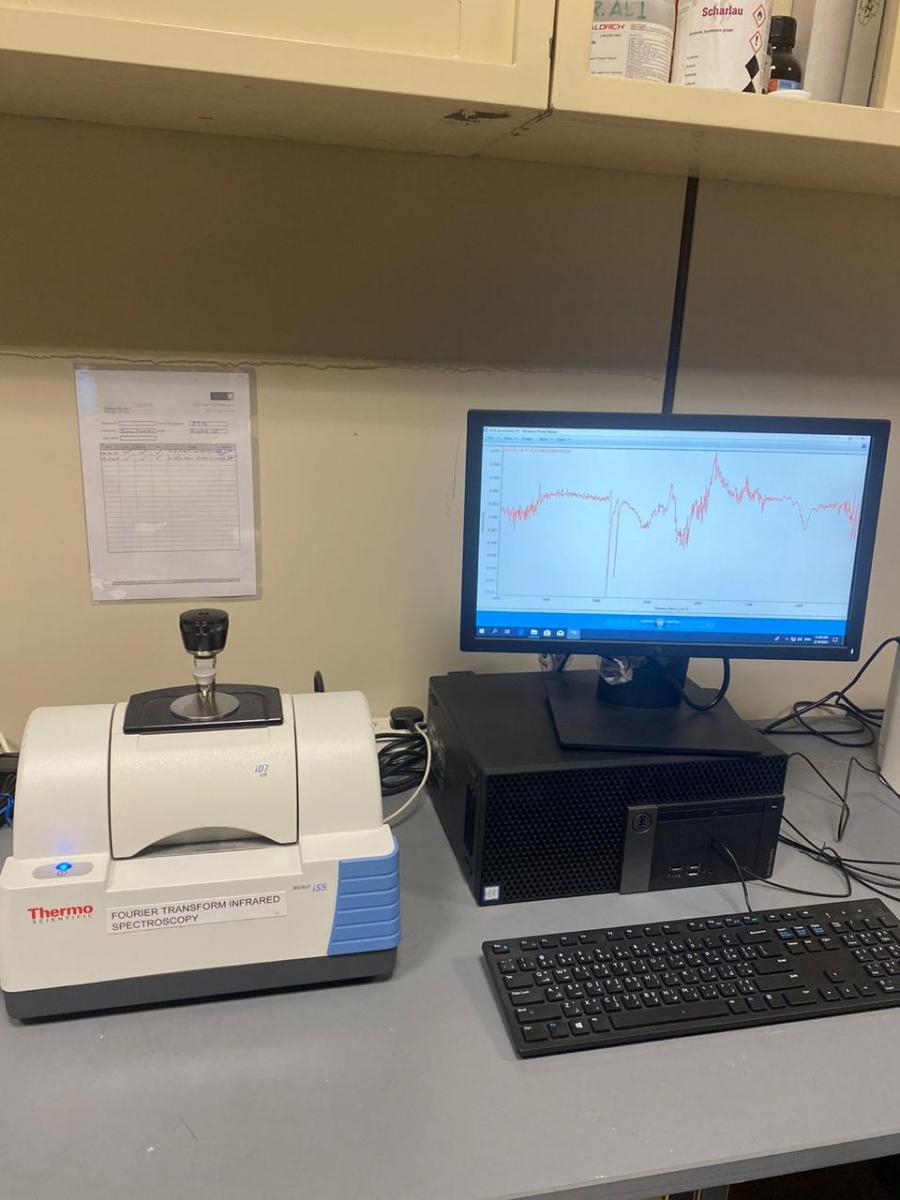

(11)

FTIR

- FTIR spectroscopy is used to quickly and definitively identify compounds such as compounded plastics, blends, fillers, paints, rubbers, coatings, resins, and adhesives.

- FTIR spectra reveal the composition of solids, liquids, and gases.

- The formation of a new chemical compound can be detected using this device

(12)

ELECTRONIC WEIGHING SCALE

- The device is used to measure the mass/weight of a substance precisely in enclosed chamber.

- The device can measure the weight as low as 0.00001 gram

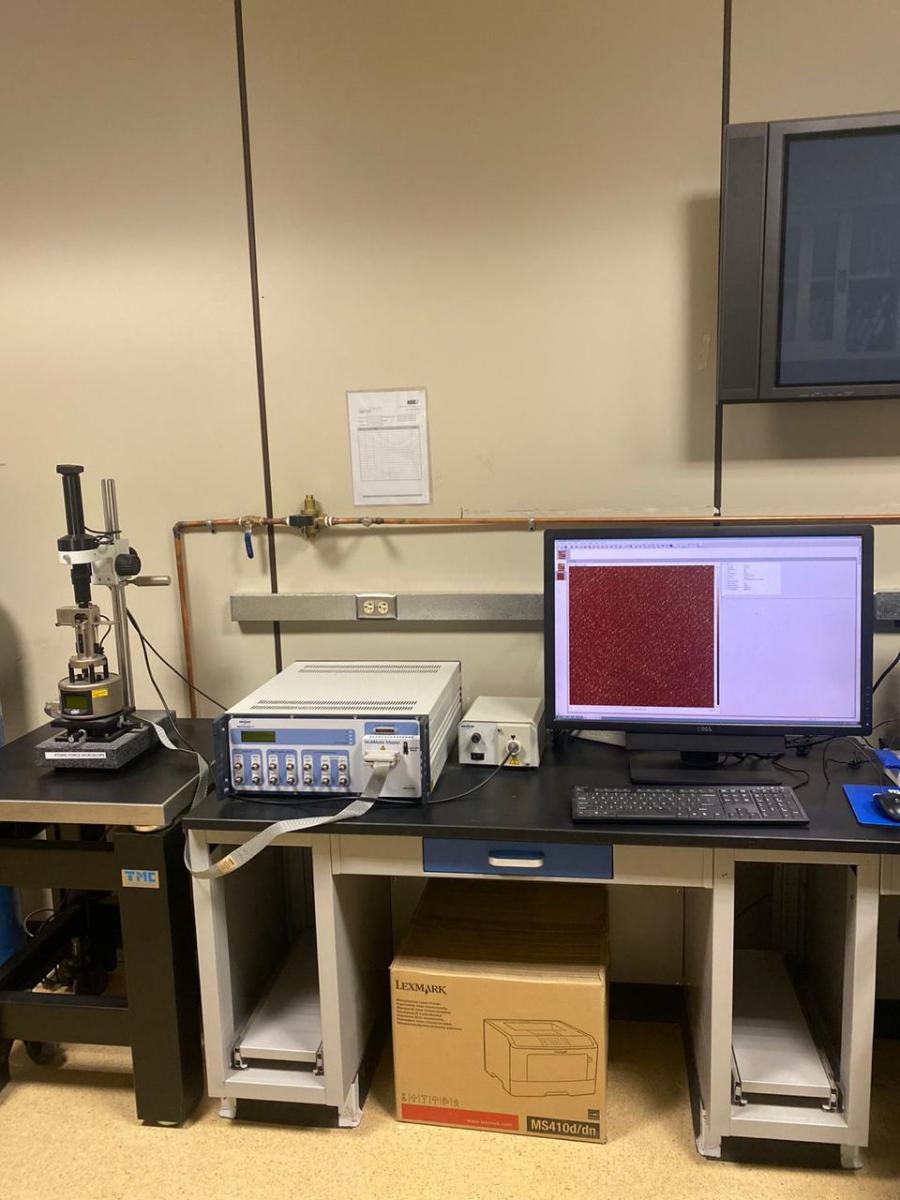

(13)

ATOMIC FORCE MICROSCOPE

- This instrument has become the most widely used tool for imaging, measuring and manipulating matter at the nanoscale

- The primary role of this device is measuring surface topography.

- It can be used to quantify the roughness of surfaces at nano level

- It can generate 3D images

(14)

THERMO CYCLER

- The device is mainly used to age a material to simulate the clinical condition

- The device is used for quick ageing of a material prior to testing of a material.

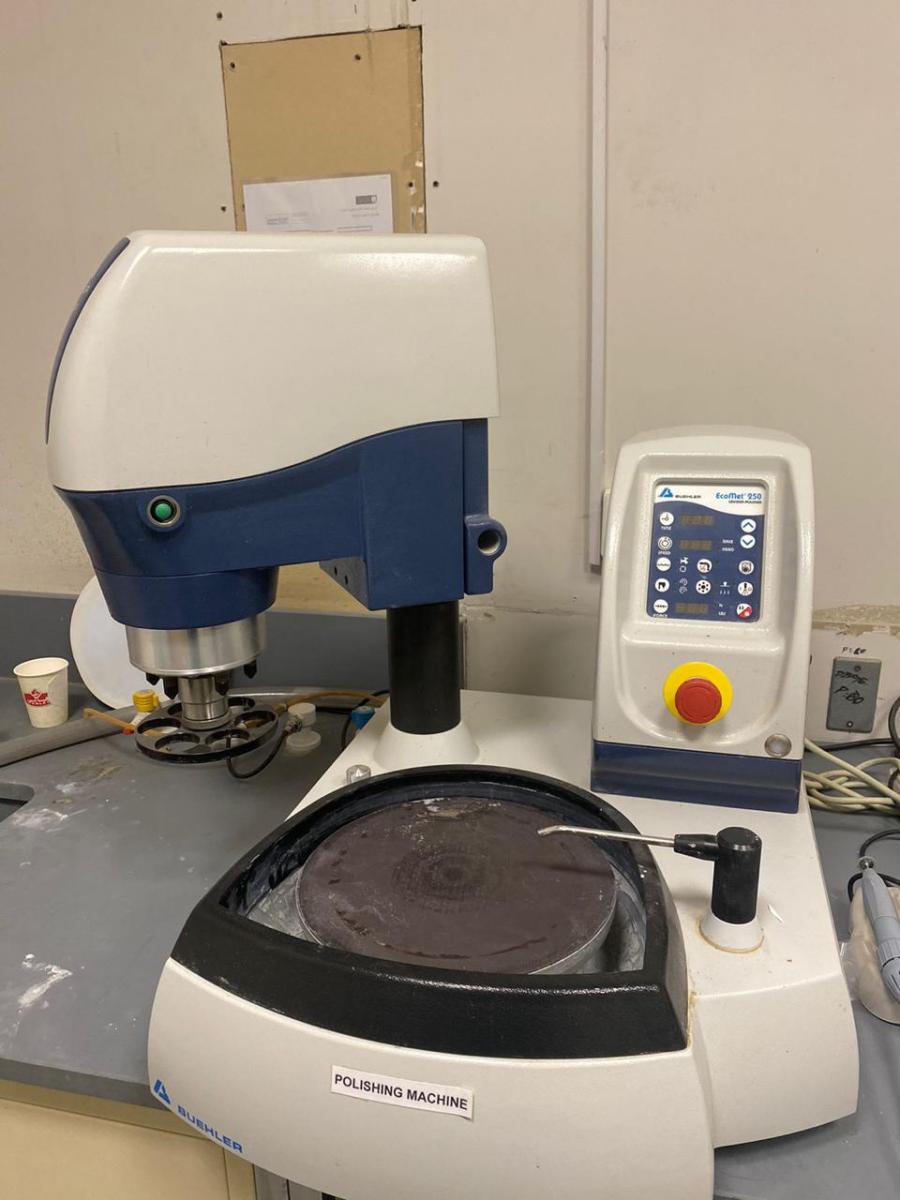

(15)

POLISHING DEVICE

- This device is used for sample preparation and finishing.

- The device polish the surface of specimen without wearing it out excessively.

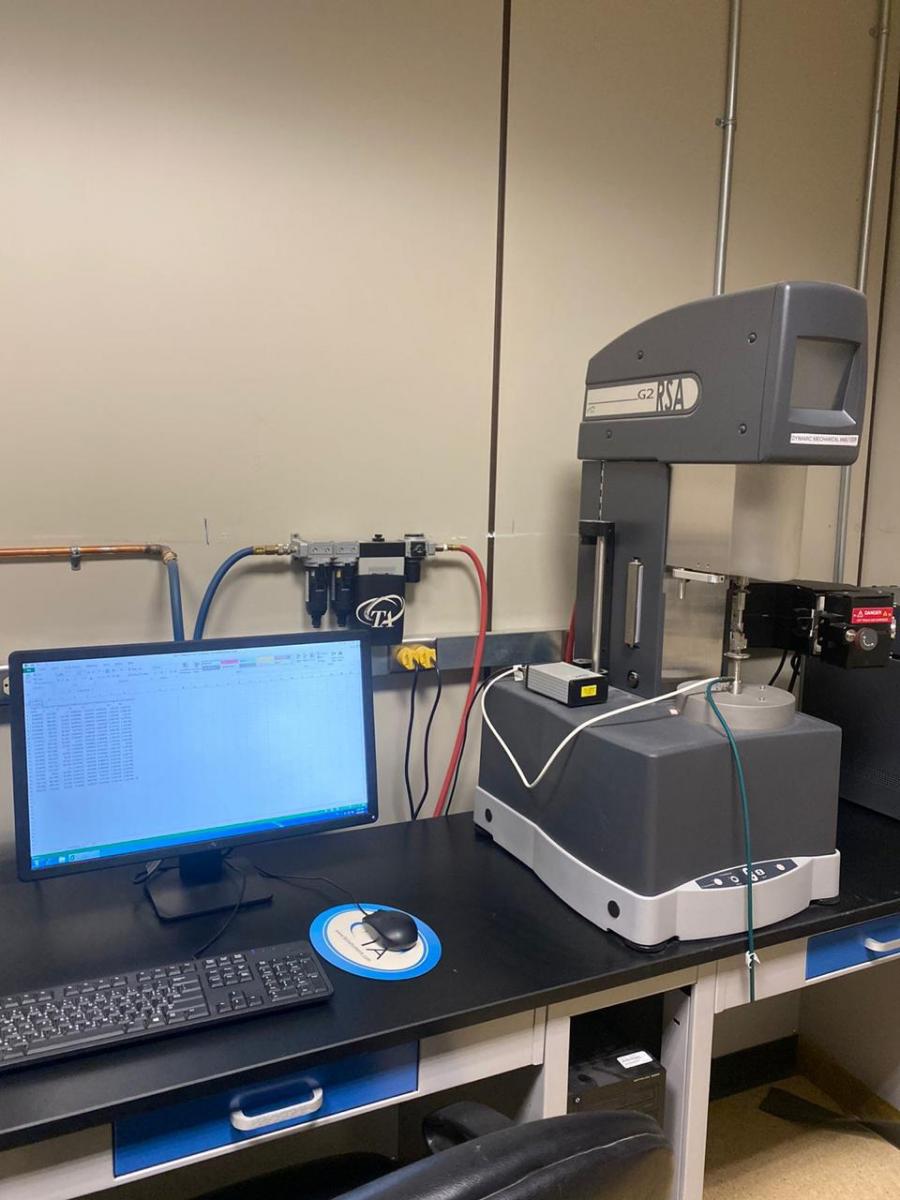

(16)

DYNAMIC MECHANICAL ANALYZER

- Dynamic mechanical analysis is a powerful and commonly used tool to study the viscoelastic behavior of polymers

- It involves measuring a material's response to an oscillating stress.

- The device can measure thermal transitions in polymers, including the glass transition temperature.